What Would You Like To Track

Designed for error proofing in a fastening sequence. This simple to install and teach vision appliance mounts above the workstation and ties to your PLC via Profinet or ethernet communication. Tool Tracker is easily taught by simply placing the tool (with affixed targets) where you want a fastening event, then clicking a mouse to create the work zone. Repeat this for each position in the sequence, and you’re done! While you’re working, the PLC enables or disables the target depending on if the target is in the correct work zone or not.

Freedom of Motion

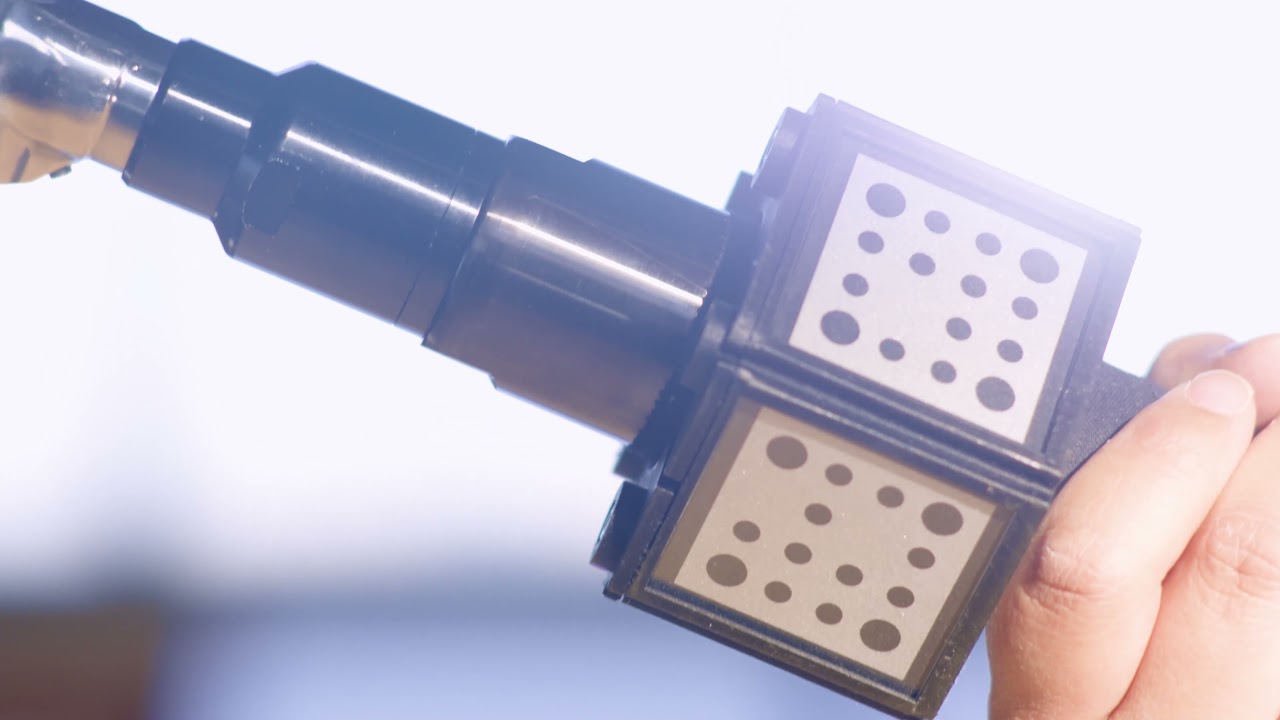

Fixed mount cameras do the tracking so no physical connection is needed to the target. The targets are passive and do not require power while providing up to 6 degrees of freedom.

Poka-yoke/ Mistake Proofing

Tool Tracker when coupled with a PLC creates an in process poka-yoke system. Enabling the target only when in the correct zone ensures the operator completes the work in the correct sequence.

Ease Of Use

Tool Tracker allows you to create zones for fastening events by simply placing the target in the desired location and clicking a mouse.

Field of View

Tool Tracker has a large field of view of approximately 1.8m x 1.2 m @ ~2.0m. This allows this system to maximize the overlap of the cameras for higher accuracy +/- 1mm.

Technical data

Core Competencies

- Tracks any handheld target in 3D

- Targets Passive (Retro Reflective)

- Vision-based tracking system

- Poka-yoke changeover

- Large field of view

- Infrared cameras

- Track moving parts

- Multiple target tracking

Technical Specs

- Power: (2.75A @ 24V, 9V-36V) – M12 5 pin male (aka 5 pin phoenix connector)

- Communications: M12-XCoded Female (aka X Coded Ethernet)

- Programming: M12-XCoded Female (aka X Coded Ethernet)

- HMI: Webpage via Programming port